At Novatug we think that from all available alternatives the CARROUSEL RAVE TUG is the best way to deal with shipping trends towards ever larger cargo ships. Port infrastructure around the world is not adequate anymore. Expanding it (if possible at all) is prohibitively expensive. Not only in terms of money, but also in terms of effort, time and environmental concerns. With enhanced control over cargo ships the CARROUSEL RAVE TUG extends the life and capabilities of existing infrastructure. And with it, it increases the safety of the crew, the tow and the port network. While saving fuel and emissions in general as well as in the maritime industry. It’s a game-changing harbour, terminal and escort tugboat.

TECHNICAL DATA

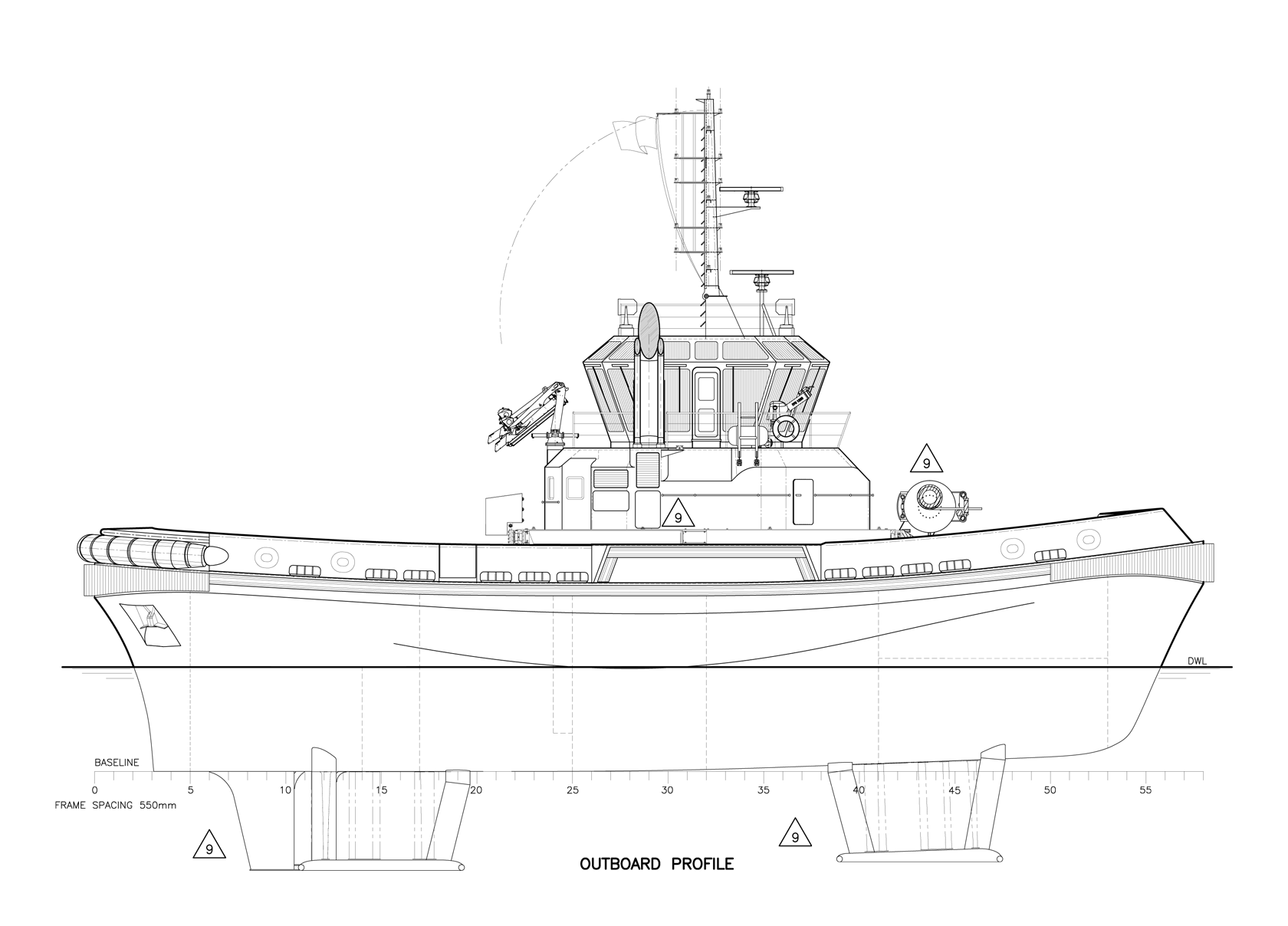

MULTRATUG 32

| Call sign | PBQM |

| Year built | 2018 |

| Classification | 1 Hull, Machinery, Escort Tug, Unrestricted Navigation, AUT-UMS, Fire-Fighting Vessel Class 1 with waterspray |

| Flag | Dutch |

| Homeport | Terneuzen-Netherlands |

| IMO | 9796042 |

DIMENSIONS

| L.O.A. | 31.90 m |

| B.O.A. | 13.20 m |

| Max. draft | 6.30 m |

| Airdraft | 16.60 m |

| Gross tonnage | 494 tons |

| Net. tonnage | 148 tons |

PERFORMANCE

| Max. bollard pull | 77 tons |

| Max. speed | 14.1 knots |

PROPULSION

| Main engines | 2x ABC 12VDZC |

| Total power | 5300 kW at 1000 RPM |

| Propulsion | 2x Voith Schneider propeller (VSP) 32R5EC/250-2 |

| Fifi type | 2x Main engine driven pump |

| Total capacity | 2700 cbm/hr |

| Fifi monitors | 2x 1200 cbm/hr – water/foam 1x 300 cbm/hr – waterspray |

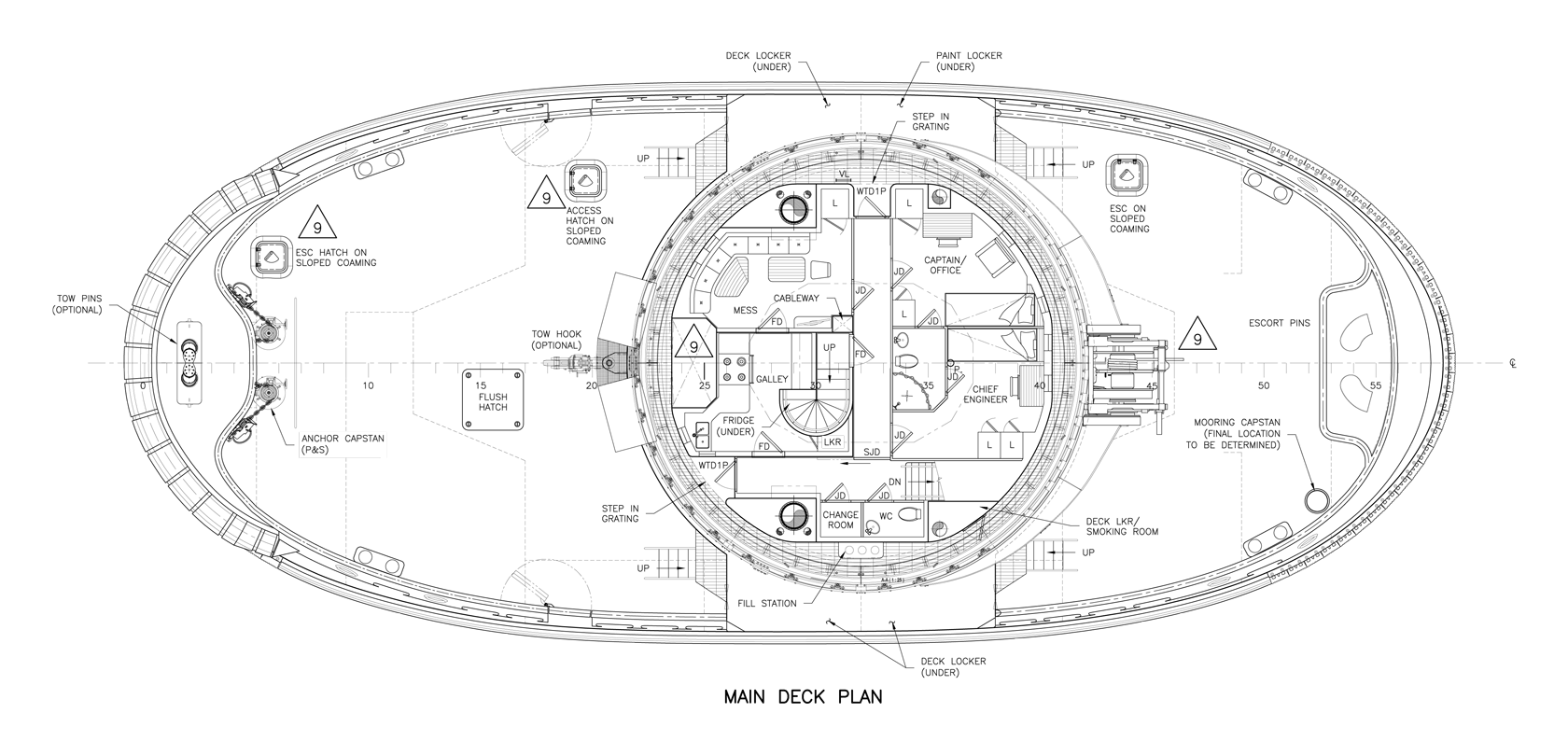

DECK LAY-OUT

| Deck space | 170 |

| Carrousel towing system | CTS-250 |

| Towing winch | 1 hydraulically driven double drum two speed pull |

| Type | CRT 200 |

| Capacity | Pull 20 ton at 10m/min |

| Brake capacity | 200 ton |

| Towing hook Aft | GSH-65 |

| Capstan | DMT – AMC-E22 K2 |

| Deck crane | Palfinger PK4501M 1000 kg/ 4.5 m |

AUXILIARY EQUIPMENT

| Main generator sets | 3x Volvo D5A-T |

| Capacity | 3x 70 kW |

| Voltage, frequency | 3x 400 V, 50 Hz |

TANK CAPACITIES

| Fuel oil | 144 m3 |

| Fresh water | 14.4 m3 |

| Lubrication oil | 5.4 m3 |

| Foam | 20.2 m3 |

| Dirty oil/sludge | 5.8 m3 |

| Bilgewater | 5.8 m3 |

| Grey water | 8.6 m3 |

| Sewage | 8.6 m3 |

ACCOMMODATION

| 1-man cabin | 2 (two) |

| 2-men cabin | 2 (two) |

| Mess room | 1 (one) |

| Galley | 1 (one) |